The Million Dollar Question for Metalier

The Million Dollar Question

For us the million dollar question has always been, how did you find us?

We always ask the people who contact us but the answer is always elusive. I was just “surfing the net” – right, what keywords did you use? What questions did you ask? I don’t know or, I don’t remember. Hey, we’re mighty pleased you got to us but we’d still love to know how.

Metalier liquid metal is an idea, a concept, that isn’t in the consciousness of most of our target market – architects and designers who would specify our products – and talented and artistic applicators who will apply and finish it.

Metalier is like metal veneer.

So how did wood veneer get started? It reminds me of an old joke about “The Happy Birthday Chicken”. What’s that? Nothing yet – but how do you think the Easter Bunny got started?

In days past people sneered at wood veneer because of what it is. Now, almost no-one would dream of using solid timber. Today people are using sheet metal when there are heaps of reasons why they shouldn’t – weight, cost, difficulty of handling, limited sheet sizes. The list goes on. But who knows to look for metal veneer?

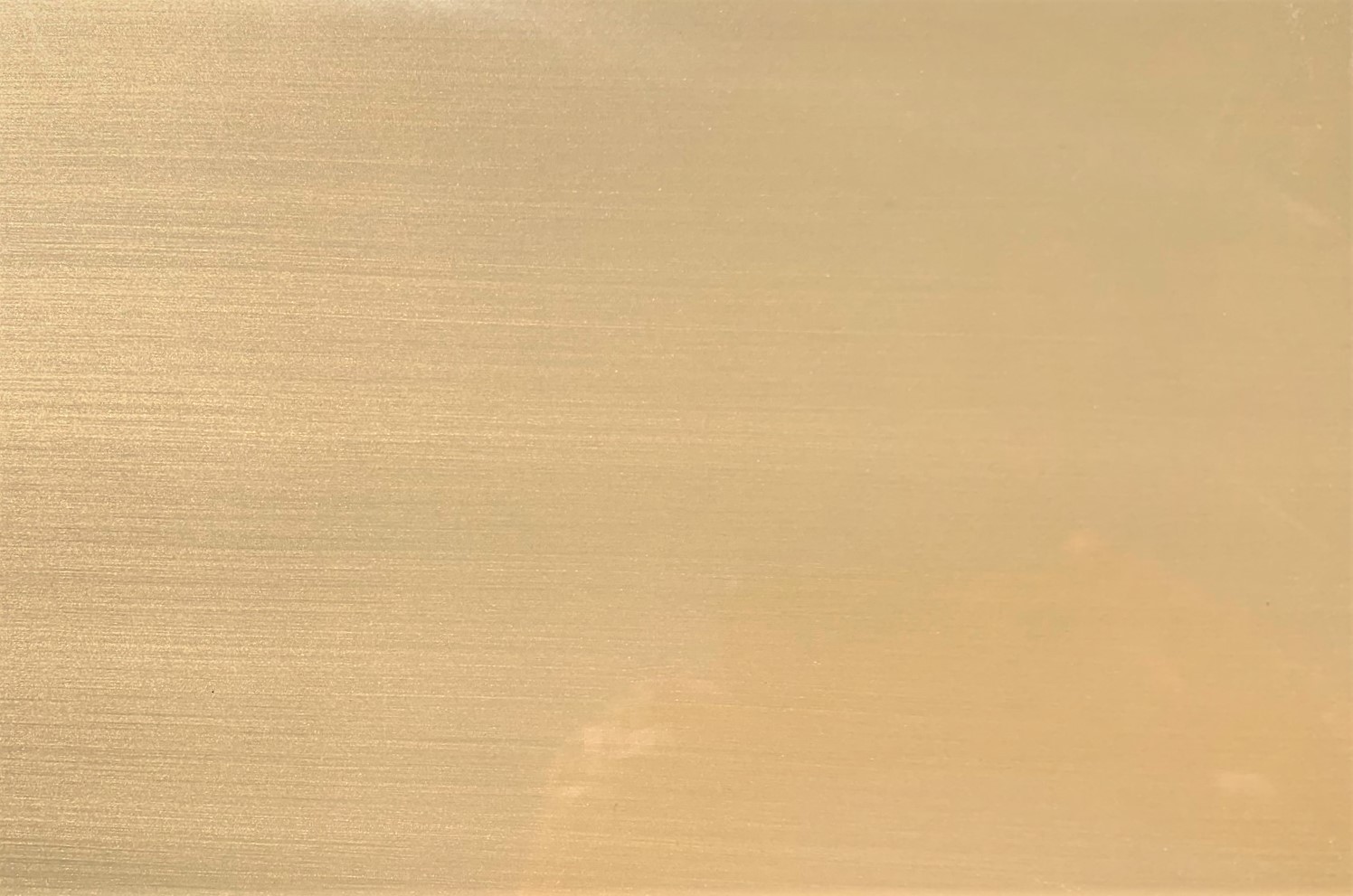

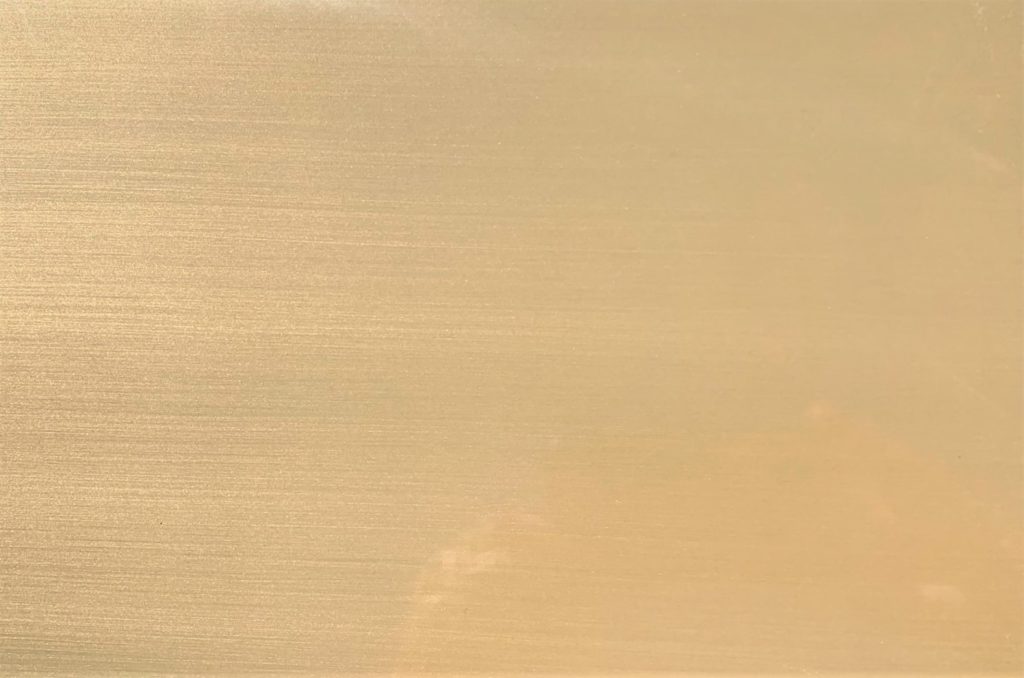

Brass/gold bring millions of dollars to mind

Which is why we chose our triple-polished brushed brass to feature in this blog. The website dark shadowing somewhat ruins the colour so here it is again. As is always the case, however, pictures never do justice to the brightness of real metal in the flesh – so to speak.

The million dollar question is a global one

Right now, the global growth areas for Metalier are India, the USA and Europe. And

no-one in all those continents can tell us how they found us. We keep asking ….

So, finding out what and why is a million dollar question with a million dollar answer.

If you can deliver the million dollar answer then, to coin a phrase,

we’re talking turkey, serious turkey.

So contact us via email, contact form, the telephone. Whats App, Facebook,

Instagram or Pinterest (not Twitter ☹☹)

with the code SERIOUS TURKEY and let’s talk – soon.

Talk to us or one of our hubs or complete the message form below.

Kitchen Design with Metalier

Kitchen design with metal

Being involved with kitchen design is one of our favourite things. It's a real treat to see the wonderful and innovative designs that usually first cross our paths as quote requests, then get into the workshop and finally are realised in the client's home.

In 2019 we worked on a fabulous kitchen design in a finish we have named water-aged brass. The brass was a real feature in the kitchen teamed with a stone bench and splash back. Although there was a professional designer involved in this rebuild, the client was very design-conscious herself and had strong ideas. Because of this she was a regular visitor to the Metalier showroom. It was a real buzz to work with her as we discussed the many options we could offer. The picture below is of the finished design. It looks stunning and our client is thrilled.

It goes without saying that she "gets" Metalier and was as keen to use as much of it as she could. As well as the kitchen we coated the statement front door in our brass moonrock finish plus two bathrooms in gunmetal bronze and another in rose pink.

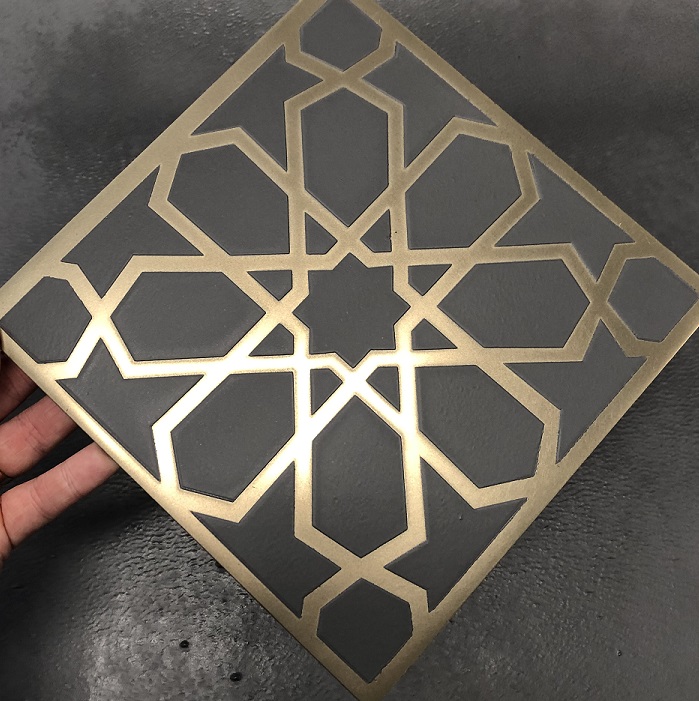

Water-aged brass

Water-aged brass is a new finish that our talented team developed. Without giving away all our secrets we can confirm that water was indeed a feature of the patina application. And in this case it was our Patina M16. A close-up of the finish is pictured below.

You may well ask why the colours of the two finishes look different. They are both brass and they are both patinated in the same way. Metal, however, whether sheet or our real metal coatings are notoriously difficult to photograph. The light plays tricks. The best way to see Metalier in the flesh, so to speak, is to request a sample.

Please contact Metalier through our hubs listed below or complete the enquiry form. And check out our other brass finishes here

Liquid Metal Dubai

Liquid Metal Dubai & the GCC

Liquid Metal Dubai is really an understatement. We should say Metalier Liquid Metal in the Middle East countries of the GCC – the Gulf Co-operating Council to be precise.

A couple of weeks back Liquid Metal Dubai and beyond became a reality when a team from New Zealand and the UK travelled to Dubai. We were there to meet with our newly appointed distributors, the Hidayath Group and to train their technicians in the application and finishing of the Metalier Coatings systems.

Welcome Hidayath

We are truly proud to welcome Hidayath Group to the Metalier team. Hidayath is a respected company in Dubai and the wider Middle East. It has been producing stainless steel for 40 years and is a significant player and contributor to the massive construction industry in the Gulf.

Hidayath's expertise is in metal

As well as its expertise in steel, Hidayath is a big player in the architectural and design market. We are delighted that the team there saw a gap in the exciting Middle Eastern market and that their extensive researches led them to Metalier.

Metalier's durability is important for the region

One of the reasons why Hidayath chose Metalier liquid metal is because of its durability. The climate in Dubai and the other Gulf States is a harsh one. Indeed, while we were there the city was under a haze. This is known as shamal and is caused by wind whipping up and swirling tiny particles of sand in the air. It hides the sun somewhat but does nothing to allay its heat. I opened the window of our hotel room to let in some warmth as the air-conditioning was a little too enthusiastic. It was astonishing how much fine grit came in during those few short moments. It became obvious when I used my computer mouse.

And on the subject of harsh climates – the exclusive Metalier protective nano clear coat is ideal for the conditions – we can’t wait to see it being a hit in the Middle East.

Liquid Metal in 2018

Liquid Metal in 2018 had a great year

We’re looking forward to an even greater year in 2019. We know it’s not considered good form to brag but we think a little brag is allowed at New Year. And the brag is that we’re growing exponentially - so contact us soon if you wish to be a part of the global success that is Metalier.

Highlights for Liquid Metal 2018 were:

1. Our new international website was launched. Live are the international site, NZ, UK, USA & Canada and Vietnam.

2. During the year we’ve worked with customers in India, Turkey, Australia, Philippines, Indonesia, Russia and Switzerland. In December we welcomed our newest distributor, the Hidayath Group in UAE. Hidayath is going to represent us in the countries of the Gulf Co-operation Council – The United Arab Emirates, Bahrain, Saudi Arabia, Oman, Qatar and Kuwait. This is an exciting opportunity for Metalier. Technical experts from Granlyn Specialist Coatings will conduct training in Dubai. HQ will assist. Metalier is becoming truly co-operative on a global level.

3. We also entered a UK “Build” competition and were awarded Leading Innovators in Decorative Coatings in -New Zealand and Best Residential Coatings Project: Freemans Bay Apartment.

Very nice. Thank you.

What will 2019 bring?

We have a new distributor from South Africa attending training at Granlyn.

We have a new distributor from China coming for training in New Zealand.

When South Africa and China join us, we will be represented in all of the continents of the world with the exception of South America. Now who do we know there? Or who do you know there?

As well as all the international excitement, we have been very busy at HQ in Aotearo New Zealand. We have been awarded wonderful local contracts and we have also been creating new and gorgeous finishes to tempt people with.

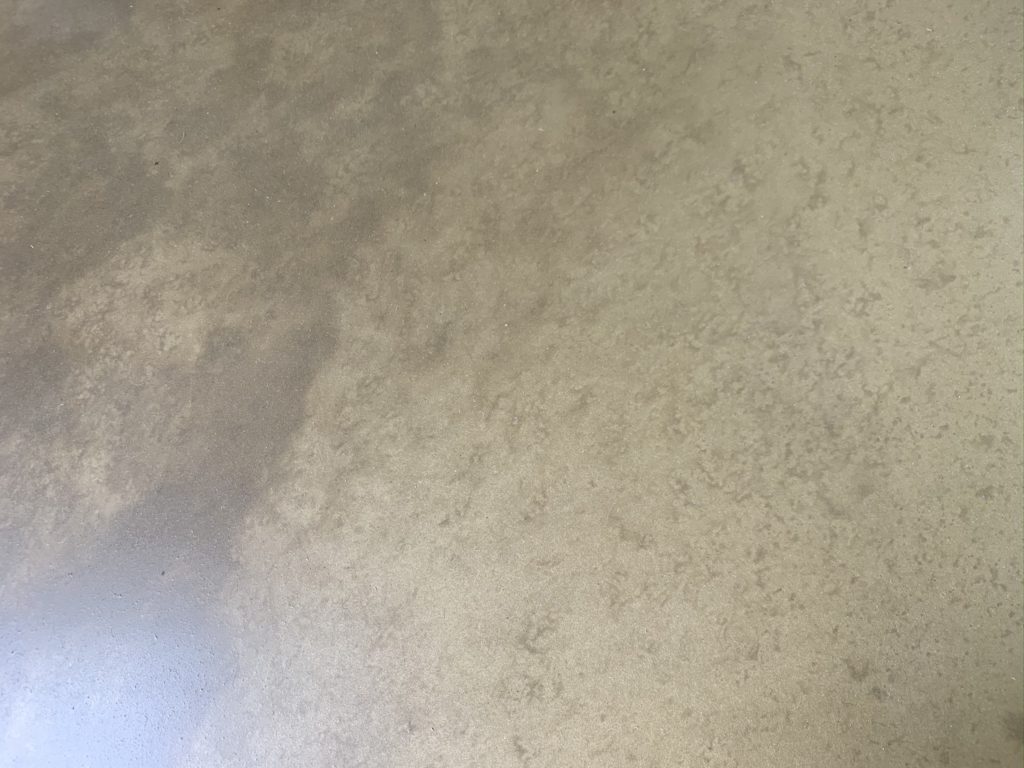

In 2018 the most popular metal by far was brass - hence the picture of our pitted brass finish currently on the workshop floor in NZ. This was despite designers predicting that 2018 was the year for copper. Judging by the work we have coming in to HQ there will be more brass throughout 2019 as well.

Contact us to talk about distribution, application or how we can make your design a magnificent reality throughout the world at your nearest hub below or HQ or you could complete the form.

Brass polish in stunning fitout

Brass polish a keynote in Auckland Apartment

Metalier coatings in a brass polish has been used to great effect on cabinetry in the lounge area of an Auckland apartment. The designer of this stunning fitout is Auckland-based designer Lauren Hare of Hare Interiors Ltd. The images are by David Straight.

Brass polish is 95% metal

Metalier Coatings are a composite of real metal powder and a binder. When sanded and polished the coating is 95% metal which makes it extremely durable. It also shines to a very high polish. Because of the composite nature of the product, however, there is an element of moodiness in it, even with a high polish. This adds movement depth and interest to the end product.

The Metalier feature provides a focus

This quality of the finished product is demonstrated by its use in this residential interior and provides a focus for the other elements of the room. The brass, gold, pink and oatmeal, together with the little floral hint in two of the cushions, add up to an interior we’re proud to be a part of.

We happen to know that there is a glorious view out the window on the left of the image. The subtleties and warmth of the décor allow a balance between the inside and the outdoors.

Lauren is a regular user of Metalier Coatings and we enjoy working with her. She prides herself on intimate detailing and a mastery of form, scale and sensitivity to materiality. We know that any project from Hare will be exciting and interesting to work on and one that we will be proud to have in our portfolio.

For enquiries contact the Metalier partner closest to you:

HQ in Aotearoa New Zealand

Or you could complete the form below:

General Contact Form

Metal Veneer | Brass | The Sugar Club

Metal Veneer | Brass showcased at The Sugar Club

Metal Veneer | Brass is showcased at The Sugar Club in the Sky Tower in Auckland City. It sits alongside sheet brass in a homogeneous glorious glamorous fit out. It’s a suitable background for Peter Gordon’s extremely scrumptious fusion food. One of our favourites is Beef Pesto. It was on the menu at Peter’s original Sugar Club back in 1987. His dining guests won’t let him take it off.

Metal Veneer | Brass in the private dining room

Private dining is the height of special. Metal Veneer | Brass is the outstanding decorative feature of the private dining area. Metal Veneer | Brass coats the MDF panels on the outside of the dining room and the inside too. A lovely cocoon of brass!

Even the Powder Room has a touch of Metal Veneer | Brass

The porthole surrounds in the Gent’s and the Ladies’ Powder Rooms are Metalier Liquid Metal Brass. You can bend sheet metal, of course, but the Metalier Solution of Metal Veneer in brass was more cost-effective and much easier to handle.

The Entrance Doors are Metal Veneer |Brass on a steel substrate

Metalier again shows its versatility on the grand front entrance doors to the restaurant. It is brass and glass. You can see them in the projects section of this website and on most of The Sugar Club’s own sites. If applying metal to metal it is necessary to create a barrier between the two metals to avoid osmosis occurring. The Metalier team are old hands at the procedure, however.

Just in case you didn't know, brass is an alloy of copper and Zinc. As well as being used in decoration brass is used in musical instruments for its acoustic properties. It is a very popular choice of metal currently and teams beautifully with white or black.

At Metalier Liquid Metal we have lots of ideas for creating beautiful things in brass – and other metals too.

Contact us to make your golden dreams come true.