Cold spray metal coating | Metalier

Cold spray metal coating – choose any substrate

Metalier is a cold spray metal coating. Sometimes it’s good to get back to basics and explain exactly what Metalier Liquid Metal is and can do.

First – because it’s cold it can be applied to almost any substrate even the sensitive ones. Think polystyrene for example as well as the obvious candidates like wood, ceramics, mdf and fibreglass. The flexible coating can be applied to fabric and cloths of all types including leather. It won’t melt or damage the substrate.

Second – no heat is part of the curing process unless you are in a real hurry and using the HP Binder. This cures in between 12-24 hours without any assistance at all. But, as I say, if you are in rush you can shorten the process to 2-3 hours with the help of infra-red lamps. The water-based and flexible binders cure in about 4 hours and they don’t like to be heated. They dry by evaporation and heat can cause them to crack if you hurry them along too fast.

No baking and no ovens

So there’s no baking and no ovens, no need for heat protection for your workers. We were highly amused by one photograph that one of the competition had on their website. No names, of course, and they’ve since taken it down. It was however a picture of a guy all done up in the heat protective gear with what looked to me like welding gear. There was even a spark coming from the work. Who did they think they were kidding?

Because its cold, Metalier’s cold spray metal coating can be easily used in in situ applications. Read the pages about our binders, solvent high performance, water-based and flexible to see which binder suits your application. And you read it here first. We are about to launch a fourth type of binder. So watch this space.

If you have a comment about this blog or any of our other musings you can leave a message below the contact form. If you’d like to be notified when the new binder (it’s a water-based one too) please contact us here or complete the form below.

General Contact Form

UK Liquid Metal | London Success

UK Liquid Metal stars at the London Surface Design Show

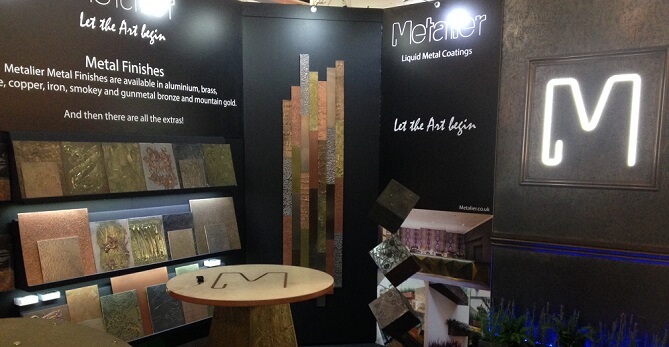

UK Liquid Metal is in the very safe hands of Craig and Alison McDonald of Granlyn Specialist Coatings. Granlyn has now exhibited at the London Surfaces Design Show for three years in a row. Every year its stand is brighter, bigger and better and this year was no exception. Once again, the Metalier stand was the star of the show. And we love Granlyn’s new strap-line “Let the art begin”. That’s exactly what Metalier is all about.

UK Liquid Metal’s stand featured Metal Coated Strand-board

It was coated strand-board that received the most comment and interest. It is an excellent example of how you can take an inexpensive material and with Metalier Coatings transform it into something amazing. This finish was featured in the Dior fit-outs in Auckland and Melbourne which were recently completed.

The Metalier stand also featured a polystyrene iron coated ball. Studded with magnets it demonstrates beyond question that this is real metal you are dealing with. It also looks so real that people lean on it. This can be a little interesting!

Lined up on the stand, dressed in Metalier Black, alongside Craig and Alison, was their Granlyn super-salesman, Steve. They need plenty of staff on hand as there are so many people who are impressed by Granlyn's creativity and want to know how they can be part of the world of Metalier.

Well done again team. At HQ, we all salute you and thank you for being part of Metalier International. Granlyn also does amazing work. If you haven’t seen The Leicester Grand Hotel you should check it out here.

To contact Craig click here.

To contact Alison click here

And to contact HQ click here or complete the form below.

General Contact Form

Bronze bowls | Metalier liquid metal

Metalier Bronze bowls were created by a design student

The bronze bowls created by design student, Shiri, resulted from her exploration of how traditional processes and materials could be complemented and extended using contemporary approaches - the best of the old alongside the best of the new.

The bronze bowls project were part of the second year Industrial Design and Innovation programme at AUT, Auckland. This programme is supported by Rebecca Dowie of Douglas and Bec. This company has been producing furniture and lighting since 2006. It has a particular focus on creators with an artisanal ethos who produce thoughtful, innovative work...an ideal fit for an AUT Studio project!

To create the bronze bowls Shiri used the precision that CNC cutting can achieve to form 'nesting' wooden forms. Her original plan had been to use cast bronze linings to her wooden bowls, but the cost to prepare and finish these, along with the weight led her to look for alternatives. Metalier cold sprayed bronze allowed her to successfully meet both practical and aesthetic objectives; the CNC lining was an exact fit to the inside of the wooden bowl, something that would have been far more difficult to achieve had it been done in conventional ways.

Michael Smythe in his recent book describes New Zealand Design as 'neither opulent nor sterile. It is accomplished with a light touch rather than a heavy hand. It delights in who it's for and how it's made. It is direct and to the point, and it doesn't take itself too seriously. It offers no 'bullshit' honesty with a twinkle in its eye..." Students were asked design more or less anything within the gamut of domestic ware, but to purposefully set about acknowledging these characteristics in their work.

An intelligent marriage of materials, sensitive use of form and materials in an unconventionally conventional bowl....a good example of Kiwi design?

Talk to us to see how we can help the twinkle in your eye. Contact us here or complete the form below.